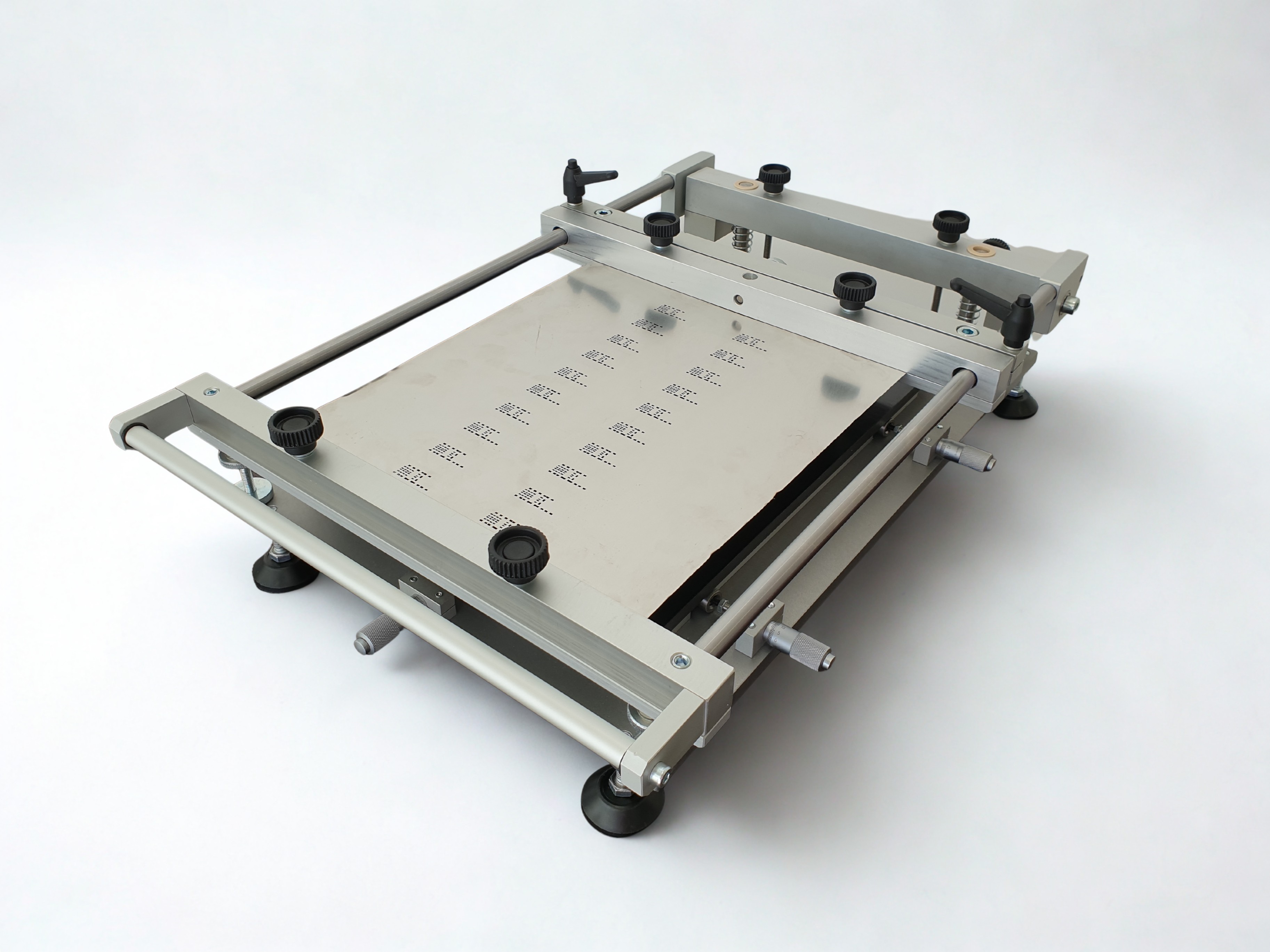

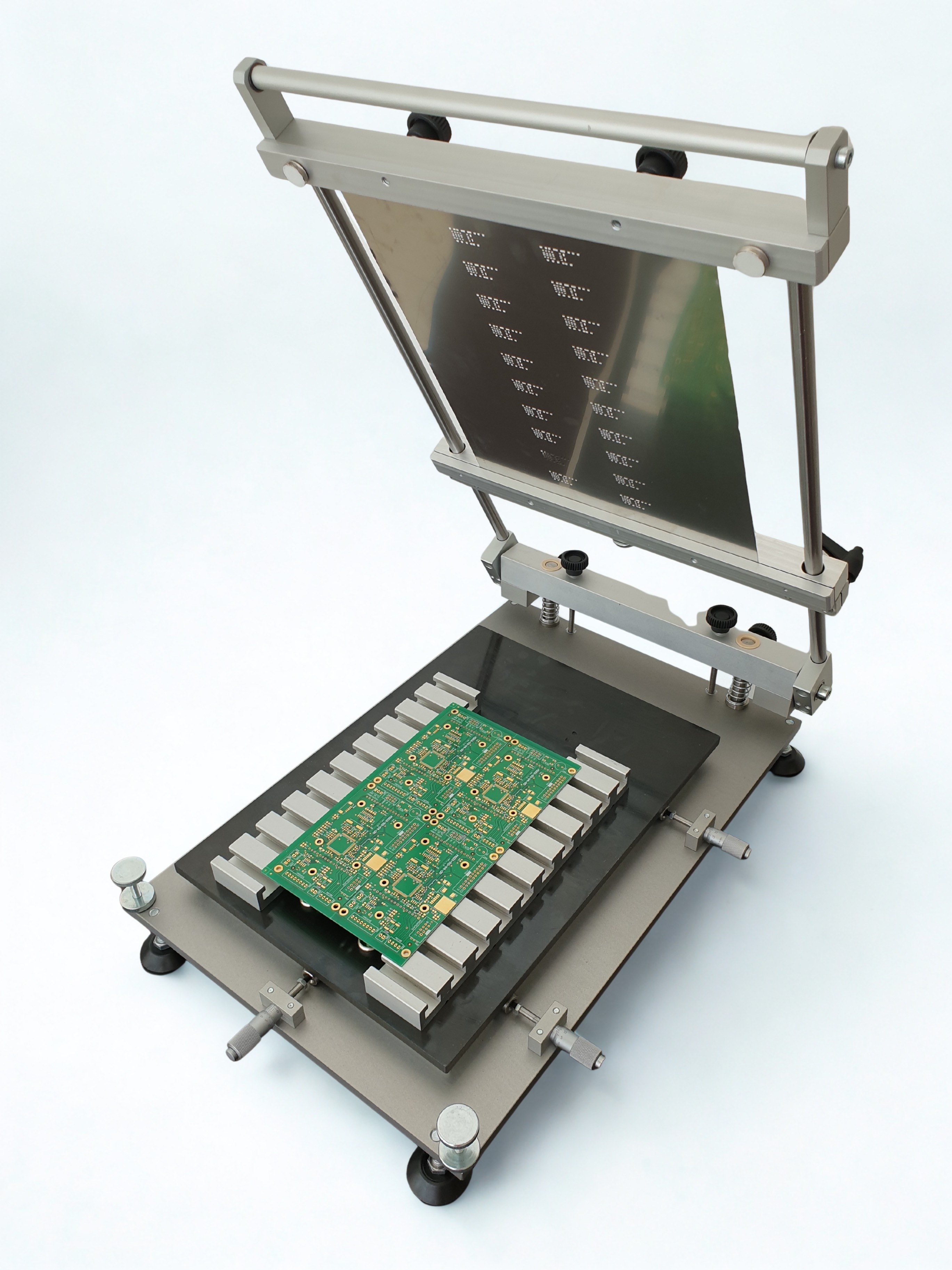

Printing results of µBGA and 0201 with the S1

S1 delivers clean and consistent print results even for challenging components like µBGA and 0201. Thanks to its precise alignment system and fine-pitch support, even the smallest pads are accurately printed, minimizing soldering defects and improving assembly yield.